By: Brian Mooney

The changing global economy creates special challenges for leaders of multinational subsidiaries. History shows that innovation is key to survival. This series of articles explores this challenge and offers subsidiary leaders a way to identify and implement innovative strategies to sustain local operations and create added value for their parent corporation. It also looks at how corporate managers can help drive more innovation from global subsidiaries.

Part 2: How National Semiconductor avoided site closure and changed their mandate

National Semiconductor (UK) Ltd was established in 1972 in Greenock, Scotland. The facility manufactures high performance analogue semi-conductors for use in data conversion and power management applications.

In the early days Greenock was one of the most competitive sites in the company. But by the mid-1990’s it had become tired, inefficient and expensive. In 1998, the site was put up for sale as part of a corporate plan to reduce global capacity.

The threat of closure spurred the management team into action. Unit cost was reduced by 50% within one year by rationalising production lines and redesigning processes. Cycle times were slashed and production yields vastly improved. Employee reskilling was undertaken as well as a major plant refurbishment.

The result was a return to levels of productivity and technical excellence that could not be matched by National Semiconductor sites elsewhere in the world. The plan to close Greenock was dropped.

A widely distributed innovation capability would be necessary to remaining competitive and avoid future threat of closure

This ‘near death’ experience taught the Scottish team valuable lessons. They realised that cost performance was necessary but not sufficient for long term survival – subsidiary strategy and core competence would be needed too. They also realised that a widely distributed innovation capability would be vital to remaining competitive and avoid future threat of closure. And they understood that site leaders needed to become much more ‘dialled into’ corporate thinking if they were going to influence decisions and maintain positive perceptions of the UK operation.

New country manager Gerry Edwards and his senior team created an action plan to bring about these changes. They began by building strong personal relationships with key individuals at corporate and business unit level. Over the next five years, these relationships helped secure further mandates and over $100m investment for the Greenock plant to maintain its world class manufacturing cost performance. They also became much more deliberately engaged with corporate HQ to ensure that strategy and activities in Greenock had direct linkage into the corporate product roadmaps.

The site attracted further corporate investment as a Design Centre serving wafer fabrication in California

In the UK, site managers developed links with local universities and government funded research programmes in analogue design and process technologies which they used to strengthen R&D capability in Greenock. This led to the site attracting further corporate investment as a Design Centre serving wafer fabrication in California.

Successful mandate migration

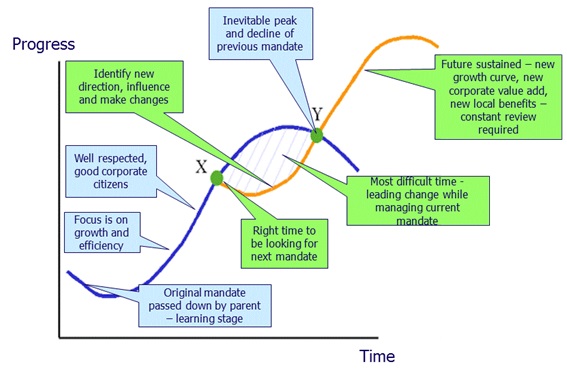

The successful transformation of National Semiconductor UK is an example of how to manage the lifecycle of subsidiary change that was introduced in the previous article:

It highlights the key innovation disciplines and leadership behaviours required to navigate the process of lifecycle performance and change:

Operational innovation: engage the talent and energy of your entire workforce to innovate and manage cost competitiveness as a critical challenge.

Core competence: build deep, distinctive and strategically relevant capabilities that sister sites around the word can’t replicate.

Entrepreneurial leadership: take control of your own destiny through positive and persuasive dealings with corporate colleagues to secure investment and evolve the mandate in line with corporate strategy.

By following these steps, subsidiary leaders can successfully migrate from the one site mandate (e.g., low cost production) to a future site mandate (e.g., global centre of excellence) and ensure on-going investment and high-value employment.

In the next article we will reveal how EMC Ireland built a 5-year innovation framework that enabled them to evolve their mandate all the way from basic assembly to advanced R&D,and become the largest EMC campus outside the US.

About the author

Brian Mooney is a Strategos Network Partner and specializes in business growth and innovation. He has led Strategos engagements around the world and has corporate experience as a general manager, strategy director and head of innovation. Brian’s expertise ranges from product strategy and consumer insight to business modelling and commercialization. He works with client teams to coach them through the process of discovery, experimentation and realization of new opportunities.

Brian Mooney is a Strategos Network Partner and specializes in business growth and innovation. He has led Strategos engagements around the world and has corporate experience as a general manager, strategy director and head of innovation. Brian’s expertise ranges from product strategy and consumer insight to business modelling and commercialization. He works with client teams to coach them through the process of discovery, experimentation and realization of new opportunities.

Series on Leading Innovation in Multinational Subsidiaries

- Changing the role of a subsidiary within a multinational

- → How National Semiconductor avoided site closure and changed their mandate

- How an entrepreneurial mindset helped EMC Ireland to change its role and position from manufacturing to become a centre of excellence