When we were asked to reinvent a carry-on trolley, we did everything except bandy random ideas about or turn the existing – profitable – model upside down. Instead, we set up a systematic 3-step approach that started with building a multidisciplinary innovation dream team including product engineers, creative designers, chemists, physicists and marketers.

Step 1: anticipate – creating the roadmap

First, we mapped out the very essence of a trolley, defined by four distinct features: performance (why do people need trolleys?), harm (what are the product’s vulnerabilities?), convenience (how user-friendly is the trolley?) and cost (what is the production cost?). This seems obvious at first sight, but these understandings are all the more crucial as innovation often involves intelligent trade-offs. For example, an extra compartment increases the trolley’s performance, but has a negative impact on its cost.

To get a better view on possible improvements, we also mapped the interactions between the product and its users. For example, at airports, we run into the issue of … trolleys bumping into people’s legs.

Finally, we launched a technology landscaping trajectory, in which we examined suitable technologies already out there. We found possible solutions to tackle the issues we found in shopping carts or even trams, using several tools:

- Scientific literature: we browsed analysis results, reviews and academic publications.

- Patent databases: we found over 10,000 patents for hand luggage or travel items.

- Textual algorithms and word clouds to visualize areas of improvement.

Step 2: create – DNA mapping and tweaking

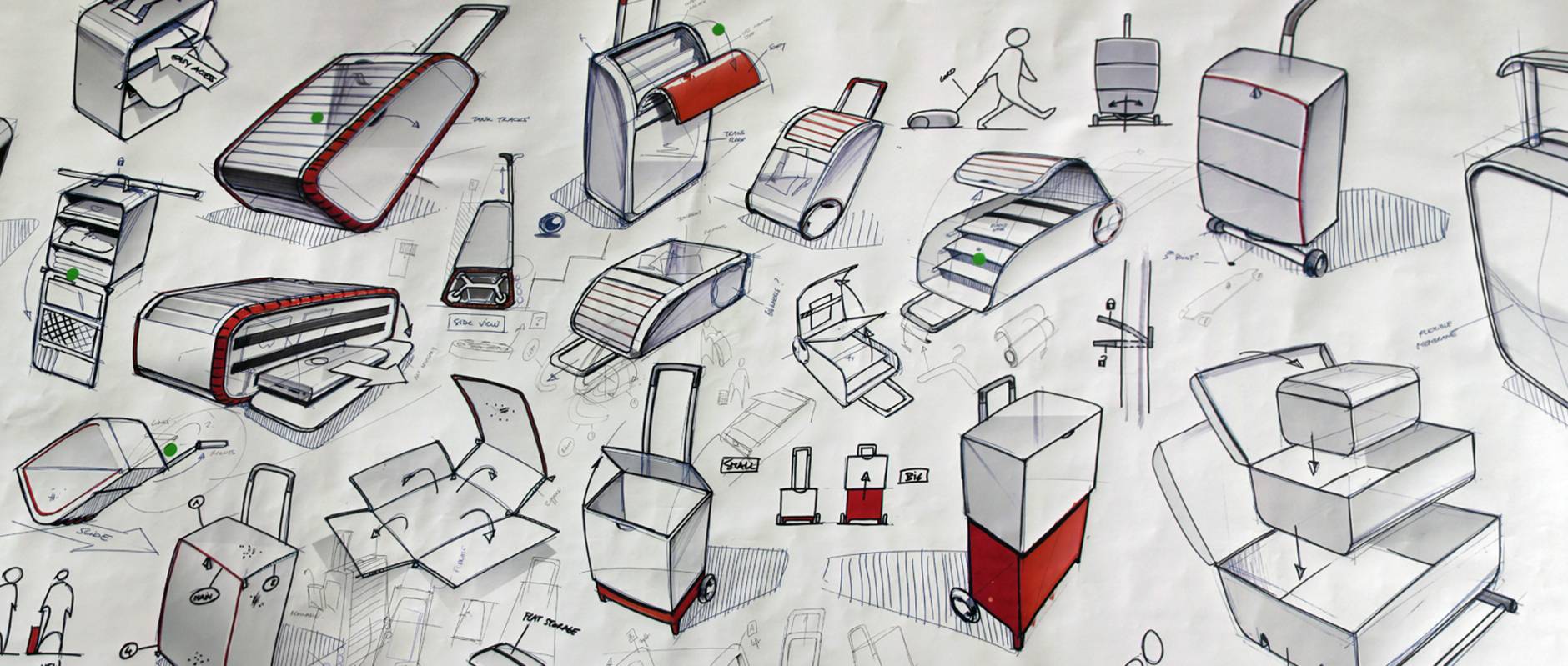

After outlining possible in-domain solutions, we expanded our view to out-of-domain analogies. This problem solving approach allowed us to come up with commercially available and easy to integrate solutions. For example, perhaps a roller shutter system could also be used to open the suitcase. Or, the function of wheels could as well be improved by the sliding system of a sledge.

During this stage, we were immersed in product properties and functions. That is why we based our research on a comprehensive dissection of the trolley’s DNA (a concept from the AULIVE method), after which we explored modifications. Eventually, we came up with the idea of an asymmetrical handle, preventing the trolley from bumping into people’s legs.

Step 3: validate – ranking, scoring and testing

From a long list of ideas and drawings to a final concept: there’s much more to it than just ‘killing your darlings’. By looking back at the trolley’s core features and possible trade-offs (see step 1), some ideas were discarded. The sledge technique, for example, turned out to be too impractical on uneven surfaces. Surviving ideas were clustered, conceptualized and ranked according to our client’s requests. This led to a shortlist of concepts.

Finally, we put our proposed innovations to the test. Our top concepts were screened further and translated into mock-ups to test their feasibility and detailed drawings for later prototyping.

The final concept – a.k.a. the trolley of the future – has a side handle for a less bumpy ride, omnidirectional wheels for easy rolling, a roller shutter to easily reach luggage in the plane, practical inside compartments and a transparent side box for travel documents.

Although we can’t emphasize the importance of a structured approach enough, each innovation challenge is different, resulting in a tailored innovation journey.

Get to know our three steps – anticipate, create and validate – and our underlying services.

About the author

In close cooperation with sales, business development and management, Diederik explores ways to expand the CREAX brand by improving the services, identifying target markets and developing strategies to communicate with them. Diederik has 5 years of experience in leading innovation projects within CREAX and is still regularly consulted to share his insights.

In close cooperation with sales, business development and management, Diederik explores ways to expand the CREAX brand by improving the services, identifying target markets and developing strategies to communicate with them. Diederik has 5 years of experience in leading innovation projects within CREAX and is still regularly consulted to share his insights.